Other

250L Small Refinery Machine

- Model: SRM-250

- Package: Standard package

- Payment: L/C, T/T, D/A, D/P, O/A, Paypal

- INQUIRY

The crude oil get from physical squeeze or other methods is mixed with suspended particles, water, phospholipids, proteins, free fatty acids, organic or inorganic impurities, which affect the edible value and storage security of the edible oil. The purpose of oil refining is to remove the useless harmful impurity of the oil for eating, storage and industrial producing.

Brief introduction of the equipment:

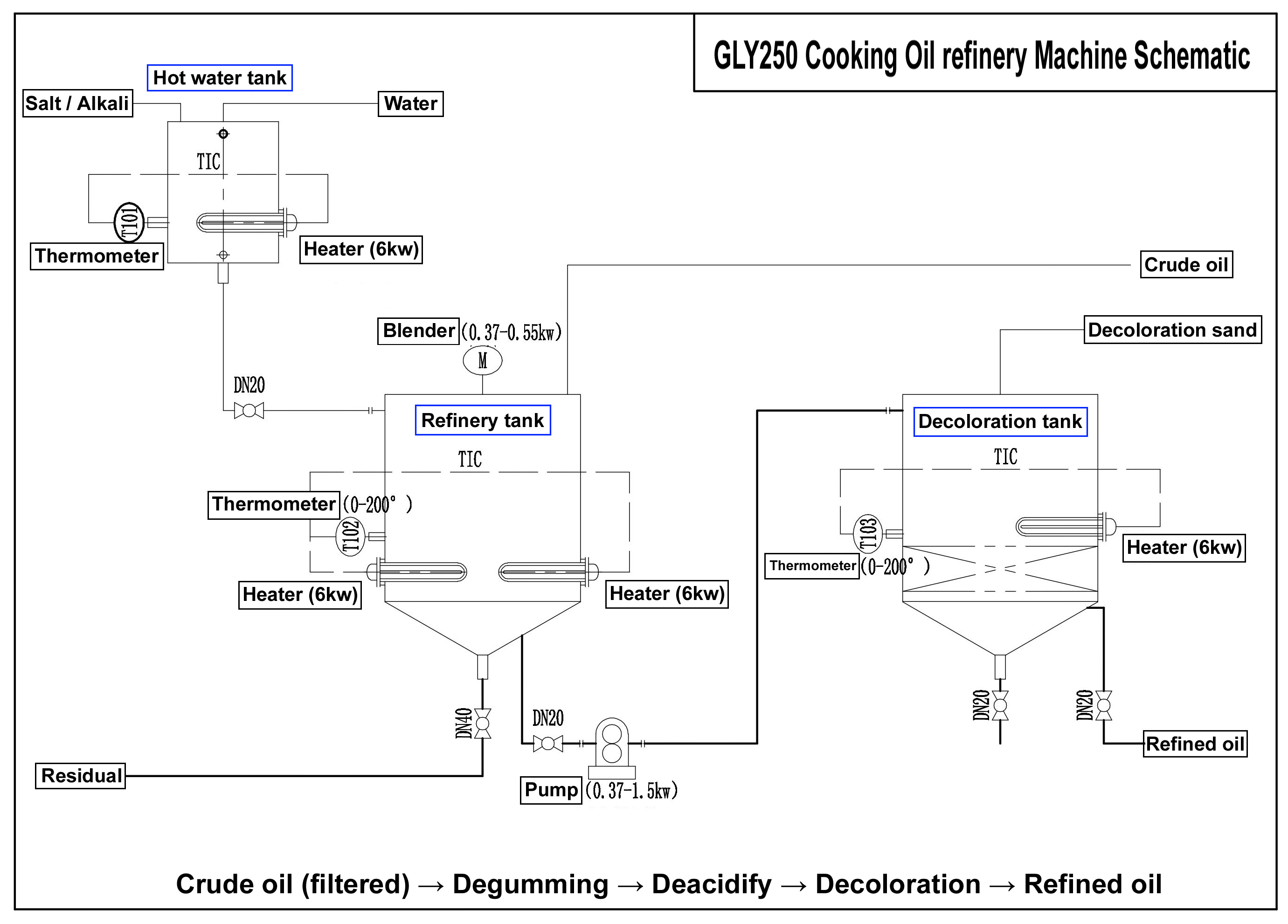

1.GLY250 small edible oil refinery is made up of refining tank, decolorizing tank, oil pump, hot water tank and electric cabinet together with the auto temperature control set, thermal insulation device and feeding buffer sets, with them it could achieve the purpose of degumming, deacidification, dehydration and decolorizing for crude oil.

2.Main parts technical parameters:

| No. | Item | Measurement and model | Power (380V, KW) | Cubage/working cubage (L) |

| 1 | Oil refining tank | DN700*1300 | 12/0.55 | 330/250 |

| 2 | Decolorizing tank | DN630*1100 | 6 | 360/300 |

| 3 | Hot water tank | DN320*600 | 6 | 26/25 |

| 4 | Oil pump | / | 0.37 | 1m³/h |

3. GLY250 small edible oil refinery producing capacity: refining tank 200-250kg/tank, decolorizing tank filtering efficiency 4-5H/tank.

The working period is effected by both the quality of crude oil and the required grade of refined oil. If the crude oil quality is good, it needs about 4 hours to reach oil grade 3 or 4 through heating, hydrating, settling, and dewatering processing steps. While the crude oil quality is not so good, but customer requires higher oil grade, it will need more than 8 hours to process a tank of oil through heating, hydration, settling, alkali-refining, wash and dehydration steps.

Operation Flowchart:

Operation Flow:

The clear pretreated crude oil (by filtering or settling), is pumped or manually poured into the refining tank. The volume is about 75% of the tank cubage (considering of adding water and oil expansion during heating). When the oil is heated to the specified temperature, add hot water to hydration degumming, or add a certain concentration of lye water to alkali degumming processing, then keep the oil settling. The oil residue should be discharged from the large drain outlet at the bottom, when the residue is fully discharged, closed the valve, heating up slowly to dry the oil. Adjust the temperature rising speed and gradient according to the situation. When the moisture of the oil meets the requirement, pump the oil to the decolorizing tank, then it is decolorizing and filtering by specified decolorizing clay, the refined oil will be pump into refined oil tank.

Categories

Support

Contact

Contact: Mr. Anson

Tel: (86-816)2223058

Fax: (86-816)2228423

E-mail: sales@vact.cn

Add: #112, Jiuzhou Avenue, Mianyang, Sichuan 621000, China.

/YZYX10_grain_oil_press_vactmachine_02.jpg)